|

Boats are supposed to be for pleasure…….that is why the boating industry coined the phrase “Pleasure Boating” and taking a “Pleasure Cruise”. However, since the congressional acts some 13 years ago that brought in Ethanol Blended Fuel into the marine market, many “Pleasure Cruises” and Family Boating outings have turned sour due to water contaminated fuel. Even if the serious boater purchases “Rec Fuel” which contains no alcohol, there still can be water contaminated problems. This article / blog post will help shed some light on what causes such problems and what boaters and service techs can do to minimize the problems. First, let’s explore some issues. How Does Water Get Outboard Motor Fuel Tanks?

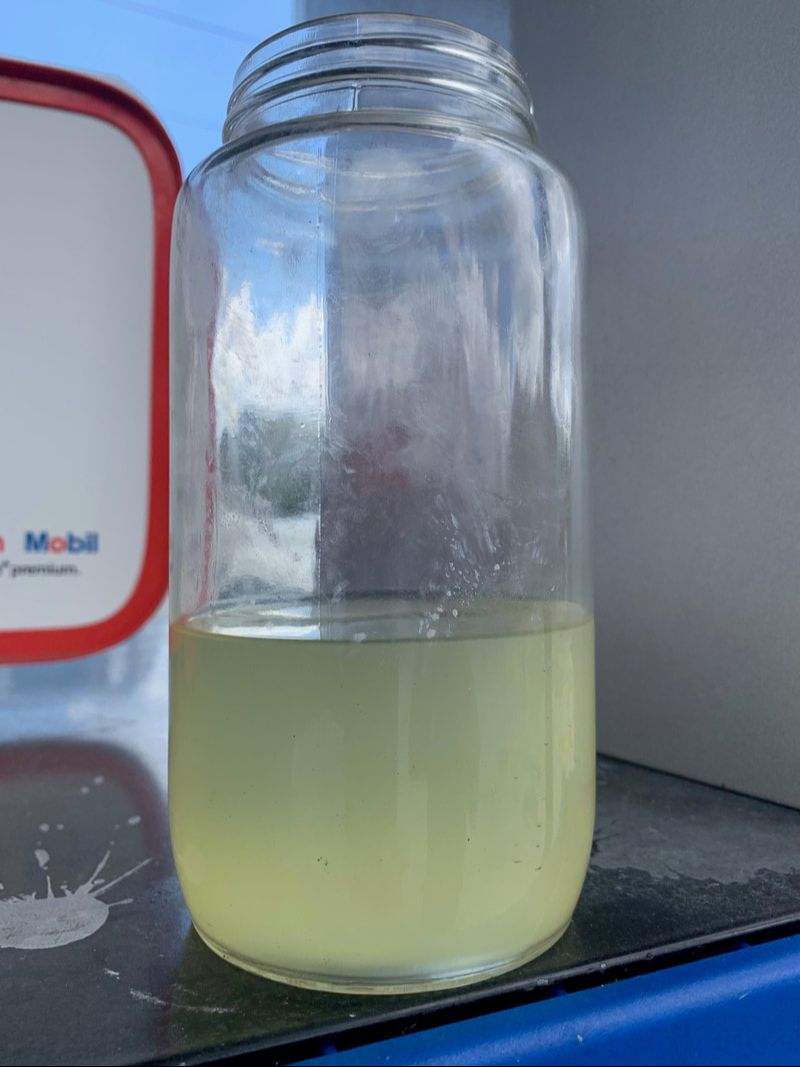

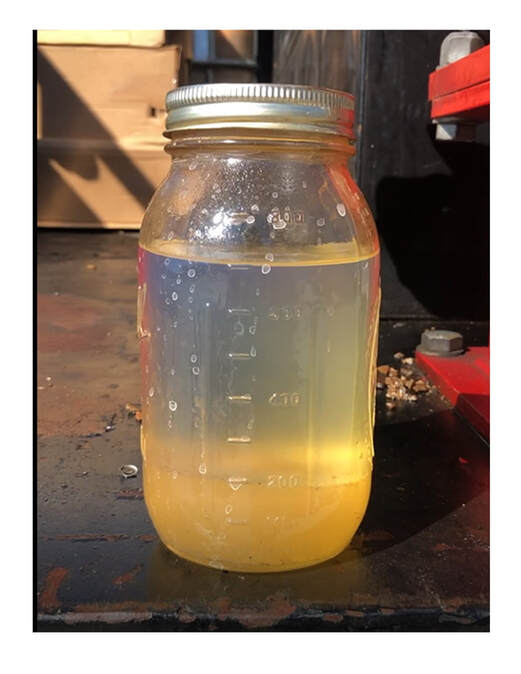

Why Is My Fuel Cloudy Sometimes, But Other Times Clear?

What Is So Bad About Suspended Water in My Fuel????

Corrosion on Fiberglass (l) and Steel (r)But What if I Already Have Fuel Water Separators to Catch Water? Won’t That Stop Water Entering My Engine? Not all fuel water separators work the same or catch all the water. Yes, you can buy a nice exterior fuel water separator that is easy to install, and has a clear bowl to let you know the water has been caught. However, what this type of filter does not tell you is how much water was able to get through to the engine. One principal used by fuel water separator manufacturer’s is called “coalescing” or the use of a coalescer. This technique takes small droplets and has actions to form them into bigger droplets, which when are directed to the outside of the filter housing. This water then falls down to a bowl and is easily drained with a pet cock valve. So, if you have such a fuel water separator, and you are experiencing poor performance, hard starts or black smoke, plus injector damage, it might that small water droplets are passing through and wreaking havoc. Examples of filters with glass bowls...how much water is getting through?So, What Are Some Steps I Can Take to Prevent and Remove Water, So I Don’t End Up With Water Contaminated Hazy Fuel in My Outboard Engine?

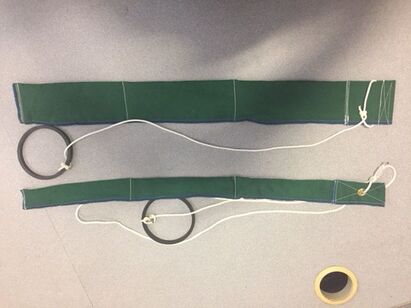

Water Absorbing Socks for Ethanol FuelsWhich filters are letting water through to the engine?

Fillrite RD 8 and Steel Camel Filters getting it doneSummary:

Water is meant swimming in pools, drinking, cooking, washing, sustaining life and many other great things. It has no good reason to be in outboard motor fuel tanks. Whether you are a boat dealer, marina, boat captain or service repair shop, pay attention to water and your headaches will go away.

5 Comments

|

�

AuthorIf you have any topics for review, please let us know. Archives

July 2024

Categories |

RSS Feed

RSS Feed