|

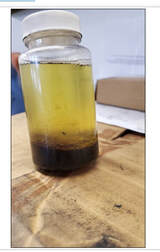

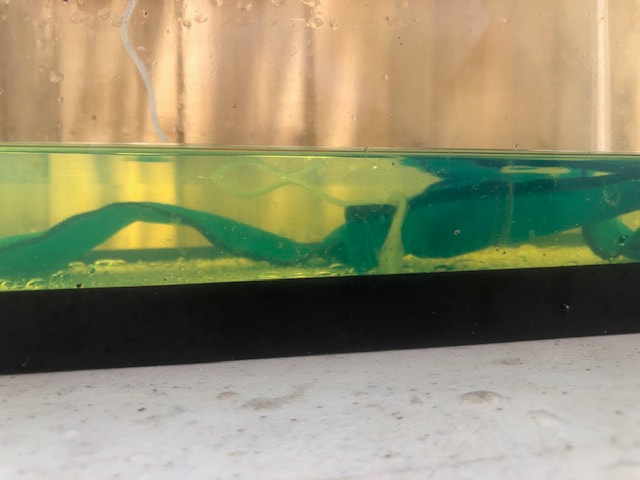

Hello Everyone In UST Inspection World: Now that it has started to rain in Florida every day and other parts of the country are getting some heavy downpours, I wanted to take a minute to review parts of 40 CFR regulations regarding liquid in containment sumps and spill buckets. 40 CFR Parts 280 and 281 Revising Underground Storage Tank Regulations-- § 280.36 Periodic operation and maintenance walkthrough inspections. (a) To properly operate and maintain UST systems, not later than October 13, 2018 owners and operators must meet one of the following: (1) Conduct a walkthrough inspection that, at a minimum, checks the following equipment as specified below: (i) Every 30 days (Exception: spill prevention equipment at UST systems receiving deliveries at intervals greater than every 30 days may be checked prior to each delivery): (A) Spill prevention equipment— visually check for damage; remove liquid or debris; check for and remove obstructions in the fill pipe; check the fill cap to make sure it is securely on the fill pipe; In the photos, you will see the liquid which must be removed. Some questions for UST Inspectors and Station Owners can be: How is the liquid being remove what is the process to properly dispose of it. Is the liquid mostly fuel or water? or combination of both? How does one make the determination? Is there any correlation between this visible water, and water entering the tank? If so, Is fuel being visually inspected by a trained employee? If the station is employing a contractor to remove the liquid? If so, are they making attempts to prevent such breaches? There is a saying amongst accident investigators, if foreign liquid or water can enter the tank.....then there is possibilities fuel can exit the tank. Despite have secondary containment......water caused corrosion is still a risk should be nipped. The following are photos of sumps filled up with the water. Did this water come through a boot, a crack or a pipe? If so most owners and inspectors know of a good contractor to fix this. If the tank is tight, it is possible that the water is coming through the lid. If the water is coming though the lids, an option might be to check out Steel Camel's line of water blocking doughs, gels and flexible gaskets. Should any inspector, station owner or contractor wish to learn more about prevention of water intrustion, water caused corrosion and fuel contamination as it applies this regulation, contact Steel Camel. www.steelcamel.com

2 Comments

So, you are driving a big load across the country and you stop at several truck stops along way to refuel… …… everything is fine, and then a fuel filter / water warning light of some form on the dashboard appears and you are forced to pay attention. While not an emergency, it is certainly a concern, particularly to truck owners who hate being down with big repair bills. So, you get out the truck or take it to a mechanic and drain the water. It is usually a pet cock valve on the bottom of the filter, and the water is easily drained into a jar for proper disposal. This no big deal, unless you are having to do it weekly or every 5,000 miles or so. So, you ask your yourself… How did this happen?

To help truck owners avoid such problems, let’s dive a little deeper into the subject water in fuel. Why Is Water Content in Fuel So Bad for My Truck?

How Does Water Build Up in My Tanks? While this can take subject can take up the whole article, we will list a few reasons.

And since, truckers hate to wait around while pumping gas or slow pumps, the fuel is moved at up to 20 gpm per pump. At that flow rate, it is just really hard to block all the water from entering the tank.

Since changes in fuel laws in the mid 2000’s, there has been many changes in fuel chemistry to meet the demands of Alternative / Green Fuel Requirements. The trend of greener fuels such as Bio Diesel will continue and will leave out any discussion or arguments on energy independence or clean air regulations for another day. Due these greener fuels, the makeup has more organics such as corn, sugar, palm leaves, soybeans and animal parts. Many folks run their trucks on refined restaurant cooking oil grease. Those qualities are great for cleaner air, but also create the problem of water bonding to the alcohols, or the water / fuel combination is hydrophilic. This issue, with agitation over long trips creates the cloudy condition. What if My Fuel is Clear, But I Still Have to Drain Water in My Fuel Bowl? In many situations, the water will separate and fall to the bottom. In these cases, you fuel filter may not be able to catch it all, so the water ends up passing onto the fuel injector and combustion chamber and that can mean big trouble down the road. What Are My Options to Control The Water in My Fuel System?

It is a given the engine manufacturer want to sell you their OEM parts. So often, it is difficult to change the filter brand or type you purchase. They do this through special configurations, threads, tools and other means. Fortunately, there is the Magnuson Act which allows for aftermarket parts that won’t void the warranty. So, in choosing an aftermarket filter for water purposes, consider the following.

Yes this takes a little time and money to research, but a whole lot less than a fuel injector job and three days of no work.

Truckers know that being stranded away from home is a terrible experience. So, one way to avoid this in association with fuel problems is to remove water that settles in the tank. The independent / owner operator has several choices.

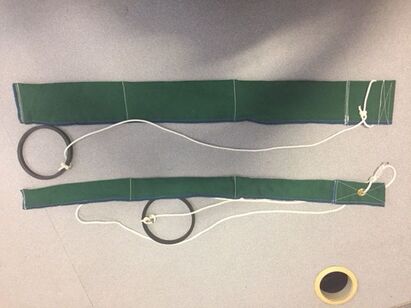

In a nutshell, it looks like an industrial Tampon and the sock with a rope that is inserted into the truck tank when idle for a day or more. The water will migrate to the sock and absorb into the chemistry. Then pull the sock out and place into a container or let it hang in a garage to air dry. Not all socks are created equal so you will have to consider:

Summary Don’t let water in your fuel system wreck your fuel injectors, schedule, budgets and bottom line. Pay attention to the water in the fuel filter bowl and lights on the dash and then tackle it, before it tackles you. Author: Dan Jenkins is a principal with Steel Camel, a manufacturer and distributor of water control products. |

�

AuthorIf you have any topics for review, please let us know. Archives

July 2024

Categories |

RSS Feed

RSS Feed