Nine Recommended Toolbox Items Every UST Inspector Should Have to Perform Effective UST Inspections.5/23/2022 There is an old saying in the crane inspection business that goes like this. “It is not the crane that wears out and causes wear and failure, it is the poorly trained crane operator that caused wear and failure.” Same goes for USTs. You can have two stations built at same time, same equipment, same fuel, and delivery schedule. One will have relatively few problems and enjoy a long productive life, the other will be full of problems and must prematurely pulled out of service and replaced…………ouch!!!!!!!!! So, what gives………in today’s world with modern biofuels, the culprit is water and not addressing water effectively and often. Ask a failure analysis person about corrosion issues in fuel tank systems, and he / she will tell you that water is often close by. It is the water that help create and accelerate sludge, acid, and delamination. Key components to premature wear and failure. The following list of tools should be employed in every UST Inspector toolbox and field inspection to help:

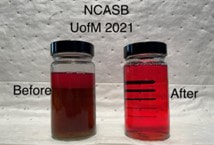

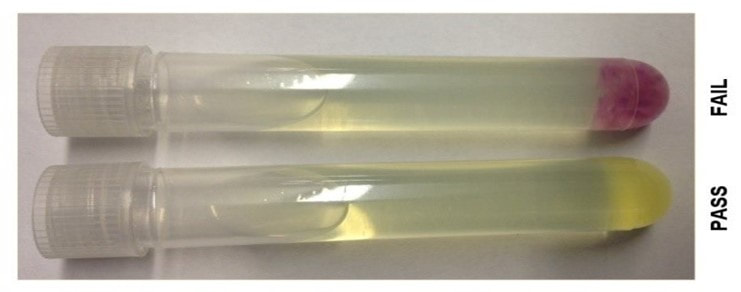

1. Fuel Sample Bailer for Measuring Suspended Water This device will measure water content in the fuel column that the paste will not detect. The paste does fine job if the tank is perfectly level, and all water has separated out and falling to the bottom…. but with modern fuels, this is rarely the case. This can be proven out with a Karl Fischer test……again, small problems turn into big problems 2. Fuel Sample Collection Bottles Whether you prefer glass or plastic, the fuel sample from the bailer should be placed in clear bottles. The inspector should then look for any haze, rust chips, sludge etc. Hazy / Cloudy fuel means water and more problems to follow. You might ask why not take the sample from the filter? The filter can catch the water and then that would not be an accurate reading of water content in the tank. 3. Water Detection Tablets or Powder For those inspectors with suspected poor vision, or just want a quick way to measure if water is suspended in the fuel, these kits are available. Early detection of suspended water is key to reducing tank cleaning and future damage to the system. 4. Camera and Notepad for Identifying Contractors That Remove Water from Tank BottomsWhile 40 CFR Parts 280 does not directly state is a violation to have water pumped off tank bottoms, there is a section that states tank owner must report an unexplained presence of water in the tank. § 280.50 And therefore, when an inspector comes across a contractor with this type of equipment, they should ask how water did they pump out and be able to explain how the water got in. In many cases, if water can get in, fuel can get out. As far as this author can tell, section § 280.50 is rarely used, but tank pump outs are commonplace. 5. Phone Number for State Inspector of Fuel Quality While each state has slightly different rules and techniques for measuring water contamination, they do share a common goal of ensuring consumers are receiving contamination free fuel.These departments also detect and record which stations have had violations for excess water in the fuel delivery. So, for the inspector who wants to see less corrosion and less damage to the fuel system and make their job easier, call you state inspection office and ask for: a) Where are the geographical hotspots for water contamination? b) What time of the year do they see the most violations for water contamination? c) What fuels have the most water contamination Diesel, Gas, Bio Blends? d) Where are the repeat offenders? And can I see their history? e) Do they follow NIST 130? Or do they use their own measurement? 6. Inspect Dispenser and Contractors Service Vehicle Storage, If Possible, to Determine What Filters Are Deployed? While this may sound invasive, it is a key indicator to determine if there are water problems.

A good question to ask owner is: a) Are you using such type of filters because you have never detected water? If the answer is yes, then the inspector should take extra efforts to measure the presence of water. b) Are you using such type of filters because contractor recommends such filters? If the answer is yes, then the inspector should take extra efforts to educate the contractor on the risks of corrosion and resin compatibility as it applies to tank damage. c) If upon inspection of Contractors Service Vehicle, the inspector discovers multiple types of water detecting or blocking filters. Good questions to ask are: d) Why do you carry so many types of water blocking or water detecting filters? While the contractor might not tell you, it is a good indicator of water problems. e) How often do you change out filters on planned maintenance on planned maintenance schedule? Quarterly, Biannual or Annual. If the contractor responds annually, then inspector should take extra efforts to look deeper into inspecting for presence of water. 7. Filter Cutter Opener and a Magnet One picture tells a thousand words. A filter cutter opener, which can be readily purchased on Amazon for under $100.00. (We use the Longacre brand) can tell inspector a lot about the condition of tanks. On the diesel filter, the inspectors should look for RUST Chips!!!!! Often the rust chips might be embedded in sludge or coffee grinds looking stuff………a magnet will confirm both metal and presence of water. Also, the inspectors should look for good ol’ nasty and gooey sludge. A sure sign of presence of water. This sludge can also create an acid which directly relates to deterioration of the fuel system. 8. Anti-Seize Product For any inspector who struggles with clamps, knobs or bolts on lifting sump lids or inspection plates, water and acid vapor contribute to the corrosion that makes the device not easy to remove. Go ahead and apply a little on threads……. this will make everyone’s job easier. 9. Non-Methylene Chloride Paint Stripper – Soy Based Paint Stripper. Since the problems of rusted STP motors came around in the mid 2000’s, manufacturers and contractors have attempted to protect such devices with paints and coatings. While it looks pretty and one can say they followed manufacturers recommendations, the acid vapors in the fuel system will deteriorate these coatings……including coating designed or aircrafts and applied properly. One these coating crack or peel, the water and acid vapors like to creep in and make some of nastiest corrosion known to mankind that can really wreak havoc. Even properly applied paint on properly prepped surfaces has rust breaking through. So, if you see paint peeling, chipping, or cracking, my advice is to remove it slowly and safely and then treat is with a true corrosion inhibitor that stands up to acid vapors. For safety reasons, choose a Non-Methylene Chloride Paint Stripper. These types of chemicals work by breaking the adhesion bond and not eating the coating. So, it might take a few days for it to work, then simply scrape or brush off with brass and properly dispose of. We have good luck with Soy Based Strippers and patience is the key. 10. Water Blocking Gel or Gaskets In 40 CFR 280 under section n § 280.36 Periodic operation and maintenance walkthrough inspections. There is a clause that states every 30 days spill prevention equipment must be inspected and that on must remove liquid or debris……and this covers spill buckets and water. And since no parking lots are perfectly level and delivery drivers are known not to be gentle on spill bucket lids, water is going to creep in. So, help yourself and your customers by making efforts to block water from entering the spill buckets and eventually the tank. One simple and cost-effective method is to employ water blocking gels and gaskets. These tools are particularly effective when spill buckets are located are located near snow piles or drains from canopies In summary, water directly and indirectly causes damage to fuel systems which increases the chances of a release. So, we recommend filling your inspector toolbox up with the proper tools to address water and employ early and often.

Author, Dan Jenkins – principal with Steel Camel

2 Comments

|

�

AuthorIf you have any topics for review, please let us know. Archives

July 2024

Categories |

RSS Feed

RSS Feed