|

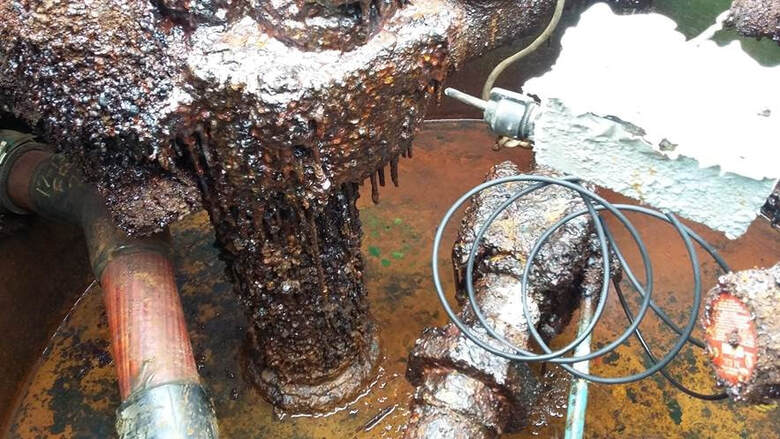

It is a given that UST sumps contain lots or dissimilar metals, often which are porous. It is also a given that there are going to some forms of water or humidity in the sumps. Also, some fuel vapors, primarily ones with organics (corn) excrete a bacteria that creates an acid. This combination results in rust that can wreak significant havoc and cause component to failure. One of the first attempts to combat this problem by industry contractors and station owners was to go to some form of paint or coating. The main reason is these products are readily available. The theory is that one can cover or smother the metal to cut off the oxygen, thus prevent rust. After seeing the results of rust coming back after six months, many contractors and station owners moved to more aggressive / durable coating and more aggressive preparation. Unfortunately, paint prep often involves removing metal, which ultimately weakens the metal. Another attempt by industry was to use an acid as preparation product such as Naval Jelly. The problems with this preparation is it requires a rinse, which creates a hazard waste. Also using acids in sumps can have negative effects on metal if not rinsed properly. The next problems contractors encountered with paints & coating was adhesion problems. The metals are porous, the surfaces are imperfect and not all metals readily accept paints and coatings. So many contractors tried to overcoat the surfaces and really smother the surfaces. What happens is the rust underneath the paint expands and causes blisters and paint no longer to adhere creating another set up problems. One problem is inspectors could not see rust hidden by the paint. Another problem was it became very difficult to remove fasteners and other components during repairs or replacement, thus increasing labor and safety concerns. Furthermore, removing paint in confined spaces is a major headache. Another problems with paints and coatings in sumps is they often the cure hard and become rigid. The problems with such characteristics is the pumps vibrate, and metals expand and contract during temperature swings. This can lead to cracks, which allow the water to creep under the paint and due further damage.

In summary, paints and coatings simply du not hold up well in confined spaces with humidity and vibration. Contractors and station owners are better off with corrosion treatments, such as the one Steel Camel offers. For additional information alternative products to paint to slow down corrosion, please contact Steel Camel at 813-877-4665

3 Comments

Dan Jenkins: Tampa, FL Long before electronic surface mount technologies were invented, moisture caused corrosion problems on metallic surfaces. From ancient swords and armor, to Egyptian jewelry to early telephone cable, metal components always want to return to its original state and the oxidation / corrosion problems process began. Early attempts to preserve and protect metal included animal fats, organic oils and coatings made from ashes, minerals and tree sap etc. In today’s world of surface mounted technology, the problems are no different. Metal components are placed in confined spaces and when temperatures change, humidity happens. When this liquid or vapor lands and sits on the metal, general corrosion occurs. Corrosion on boards causes failures, and failures cost the industry millions of dollars to fix. To protect these boards from failure moisture induced corrosion, manufacturers, assemblers and packagers have turned to different technologies to solve this issue. One way is with a conformal coating which is thin film. Often times they work great and there are no problems. Other times, the crack and cause all types of problems, including removal. In this article we will focus on different types of drying agents or desiccants. In another article we will cover other types of corrosion occur such as pitting, galvanic and stress. Let’s start of my understanding what a desiccant is and does. A desiccant is basically a drying agent. Most folks are accustomed to seeing them in pill bottles, vitamins and beef jerky. Today, many in the surface mount technology community are seeing them show up in individually packaged components. One of the reasons for this is the Military Specification D-3464. This specification was written in 1967 with minor revision in 1987….that was a long time ago. This spec calls for a desiccant which acts as an adsorbent, not be confused with an absorbent. While the words sound the same, they have different meanings. An adsorbent works by moisture sticking to the surface of desiccant. An absorbent works by the moisture being soaked up and held by the substrate. A baby diaper works on this principle; however, a baby diaper will not grab moisture from the air. If you get deeper into industry specs and industry standards such as the Joint Electron Device Engineering Council (JEDEC) Institute for Printed Circuits IPC, you will find they too reference the Mil-D-3464 spec, which includes a placement of adsorbent desiccant and a Humidity Indicator Card. So, what’s the problem? If the spec is good enough for the military and good enough for the two leading PCB / electronic associations, why should I care?.....Here is why… The adsorbent, often times referred to as Silica Gel Beads or Molecular Sieves are basically dried sand or Silica, baked in an oven. The baking creates tons of miniature cracks that help adhere the moisture to the surfaces. Sounds great on the surface, but let’s look a little deeper. Disadvantages of Silica GelThere are two main problems. First, due to the material being rigid, the beads do not hold much moisture. So, if your boards are sitting in a hot warehouse or on a ship with lots of temperature changes, the Silica Gel beads can’t handle the volume of moisture and the HIC is triggered. The second main problem is knockoffs and quality checks. Due to the low cost of raw materials, many bags are made overseas and in large volumes which makes quality control difficult. Advantages of Silica GelThey are incredibly inexpensive. A simple 2”x2’ bag can be as low as .25 cents and if you purchase them in China, you can get them for .12 cents. Another advantage of Silica Gel beads are they are treated with chemical dye which will provide a color change to alert the operator when to change out. There are some who claim Silica Gel beads can be regenerated in an oven, but with that low of price, why bother. Advantages of AbsorbentsAbsorbents, such as the Moisture Hog sold by Steel Camel, not only feature an expandable surface to grab more moisture, but they also hold the water by converting water into a non-water element and make it dry. See video youtube.com/watch?v=kli3OMrFUD4) Another advantage of Moisture Hog absorbent is will seek out moisture lurking in the package. Due to these features, the operator will be able to desiccate a much greater volume of air, thus put more board in per package. Often 10 to 15 time more volume. This feature saves labor and packaging material. Another advantage of Moisture Hog absorbent is the change indicator. Instead of a color change, the Moisture Hog bag will change shape and texture. Depending on the situation, it will either blow up like a pillow, or get hard like a rock to notify the operator a change is needed. Disadvantage of AbsorbentsThe Steel Camel Moisture Hog price per bag is more expensive compared to Silica Gel and Molecular Sieves. Often 10-15 times more (which offset by the volume of air desiccated) Another disadvantage is they chemistry cannot be regenerated. Finally, availability. Steel Camel is not Walmart or Amazon. Expect 5-7 days for delivery in the US, 8-12 days abroad. Summary:If you are not having and moisture problems, rejected shipments or component failures due to moisture, stick with Silica Gel Beads and Molecular Sieve adsorbents. If you are having such moisture problems, consider trying the Moisture Hog by Steel Camel…..particularly for your expensive critical moisture sensitive devices. Dan Jenkins, principal at Steel Camel can be reached at 813-877-4665 or [email protected]

|

�

AuthorIf you have any topics for review, please let us know. Archives

July 2024

Categories |

RSS Feed

RSS Feed