|

In the world of greases, there are many different types of compounds, additives and manufacturing techniques used to develop products that benefit the customer’s desire to protect and lubricate parts. This wide variety will stretch from high heat applications on engines and exhaust components, to bearings on heavy equipment down to mating critical electrical components. Additional factors that go into developing grease-based products include: · Viscosity / Thickness……….how well is spreads and how stable it is and how well it performs under friction. · Temperature Range which includes melting point and how well it works in cold applications. · Water / Corrosion Resistance · Electrical Conductivity…both promoting or blocking. Additional factors can include food safety, flammability, color and costs. The following information pertains to Steel Camel’s Thread N Post use of a Lithium based grease for its three main applications. Threaded Bolts, Battery Terminals and Electrical Connections. Threaded Nuts and Bolts Steel Camel’s Thread N Post was originally developed as a general-purpose grease for mechanics that incurred Frozen or Rusted Bolts that made for difficult disassembly. These applications were primarily around saltwater applications used with heavy industrial equipment such as cranes, marine barges and pumps. From these applications, we chose to use a Red Lithium grease and developed a corrosion additive and blending package that helped mechanics avoid frustration with loosening bolts in hostile environmental conditions. By reducing corrosion and providing a solid lubrication package, the nuts and bolts were able to come apart much easier….mission accomplished. However, Thread N Post does not work in high temperature applications over 325 F, nor does it work in extremely cold temperatures below 5F. Electrical Connections Over the years, we continued to focus on helping mechanics and tinkered with our additive packaging to focus more on solving corrosion problems on single electrical pin connectors, wiring harnesses, light bulb bases etc. Unlike dielectric grease which is a barrier to block water and conductivity, we chose to focus on promoting electrical conductivity. Our customers like this feature as the corrosion package holds up in hostile environments. These features help mechanics with many general needs on applications such as boat trailers, cars and machinery. Due to Thread N Post promotes electrical conductivity and we don’t want electricity jumping to nearby components or pins via the viscous grease, Steel Camel offers a liquid version for multi pin connectors and spraying on electrical panels. Battery Terminals Over time, customers started using Thread N Post on battery terminals to not only prevent corrosion, but to tackle existing corrosion. Thanks to YouTuber Roger at Studio VRM detailed 5 months study Show link Thread N Post usage on battery terminals began to spread across the globe and gain devoted fans. Today the usage on battery terminals is spreading from typical lead acid, to all kinds of batteries including those found on Toyota Hybrids. While testing is ongoing, the feedback is quite positive. Sticks To Your Nuts For certain applications where nuts and bolts seize making the mechanics life miserable, the competition uses products which contain elements of metal to help prevent the seizing. The product category is often labeled as an “Anti Seize.” And, for the most part these metal based compounds work well in high temp applications for engines and exhaust…….however, the product has a severe draw back……its adhesion is so aggressive, that the product sticks to mechanics hands and is super difficult to get off. This makes for problems with both the skin and appearance to family and friends. This reality is frustrating To mechanics. Over the years, we have found many mechanics use anti seize with metal compounds for low temperature threaded bolt applications for on material handling equipment, marine barges, turnbuckles on sailboats etc.

And these mechanics suffer from the strong adhesive properties that sticks to their hands. When these same mechanics used Thread N Post in these applications, they were very pleased with the results when removing the nuts and bolts. The comments back to Steel Camel was pretty clear, they liked the fact the Thread N Post stuck to their nuts……..not their hands, thus the tagline was born. Summary: There are many greases on the market and not all are created or priced equally. And just about every auto parts store has several you can choose from for different applications. But for those mechanics who hate dealing with rusted bolts, electrical interference, corrosion on battery terminals and silver stuff stuck to their hands, it might be time to experiment with Steel Came’s Thread N Post. The product can be purchase online at

0 Comments

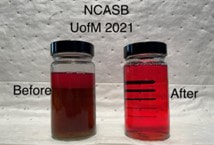

This past month here at Steel Camel we conducted our very own Desiccant Bag experiment. The test was used to measure the performance characteristics of bagged absorbent and adsorbent desiccants used to help maintain a moisture free environment to prevent damage to Moisture Sensitive Devices (MSD). The material in MDS's can include, but not limited to metals, plastics, and electronic parts. Metals can include copper, brass, and iron. The main outcomes of the test that we gathered were.

Procedures for Test Implementation

In addition to our results posted below here is a link to our Youtube Channel where you can find the more in depth explanation of the experiment as well as a link to Hazzbro who also conducted a test on our Desiccant Bag Steel Camel: https://www.youtube.com/channel/UCmF7UKedBFm2MG9jrBhp2Yw Hazzbro: https://www.youtube.com/watch?v=64uBygiOFoQ For more information contact Steel Camel at 813-877-4665 or email us at [email protected] Nine Recommended Toolbox Items Every UST Inspector Should Have to Perform Effective UST Inspections.5/23/2022 There is an old saying in the crane inspection business that goes like this. “It is not the crane that wears out and causes wear and failure, it is the poorly trained crane operator that caused wear and failure.” Same goes for USTs. You can have two stations built at same time, same equipment, same fuel, and delivery schedule. One will have relatively few problems and enjoy a long productive life, the other will be full of problems and must prematurely pulled out of service and replaced…………ouch!!!!!!!!! So, what gives………in today’s world with modern biofuels, the culprit is water and not addressing water effectively and often. Ask a failure analysis person about corrosion issues in fuel tank systems, and he / she will tell you that water is often close by. It is the water that help create and accelerate sludge, acid, and delamination. Key components to premature wear and failure. The following list of tools should be employed in every UST Inspector toolbox and field inspection to help:

1. Fuel Sample Bailer for Measuring Suspended Water This device will measure water content in the fuel column that the paste will not detect. The paste does fine job if the tank is perfectly level, and all water has separated out and falling to the bottom…. but with modern fuels, this is rarely the case. This can be proven out with a Karl Fischer test……again, small problems turn into big problems 2. Fuel Sample Collection Bottles Whether you prefer glass or plastic, the fuel sample from the bailer should be placed in clear bottles. The inspector should then look for any haze, rust chips, sludge etc. Hazy / Cloudy fuel means water and more problems to follow. You might ask why not take the sample from the filter? The filter can catch the water and then that would not be an accurate reading of water content in the tank. 3. Water Detection Tablets or Powder For those inspectors with suspected poor vision, or just want a quick way to measure if water is suspended in the fuel, these kits are available. Early detection of suspended water is key to reducing tank cleaning and future damage to the system. 4. Camera and Notepad for Identifying Contractors That Remove Water from Tank BottomsWhile 40 CFR Parts 280 does not directly state is a violation to have water pumped off tank bottoms, there is a section that states tank owner must report an unexplained presence of water in the tank. § 280.50 And therefore, when an inspector comes across a contractor with this type of equipment, they should ask how water did they pump out and be able to explain how the water got in. In many cases, if water can get in, fuel can get out. As far as this author can tell, section § 280.50 is rarely used, but tank pump outs are commonplace. 5. Phone Number for State Inspector of Fuel Quality While each state has slightly different rules and techniques for measuring water contamination, they do share a common goal of ensuring consumers are receiving contamination free fuel.These departments also detect and record which stations have had violations for excess water in the fuel delivery. So, for the inspector who wants to see less corrosion and less damage to the fuel system and make their job easier, call you state inspection office and ask for: a) Where are the geographical hotspots for water contamination? b) What time of the year do they see the most violations for water contamination? c) What fuels have the most water contamination Diesel, Gas, Bio Blends? d) Where are the repeat offenders? And can I see their history? e) Do they follow NIST 130? Or do they use their own measurement? 6. Inspect Dispenser and Contractors Service Vehicle Storage, If Possible, to Determine What Filters Are Deployed? While this may sound invasive, it is a key indicator to determine if there are water problems.

A good question to ask owner is: a) Are you using such type of filters because you have never detected water? If the answer is yes, then the inspector should take extra efforts to measure the presence of water. b) Are you using such type of filters because contractor recommends such filters? If the answer is yes, then the inspector should take extra efforts to educate the contractor on the risks of corrosion and resin compatibility as it applies to tank damage. c) If upon inspection of Contractors Service Vehicle, the inspector discovers multiple types of water detecting or blocking filters. Good questions to ask are: d) Why do you carry so many types of water blocking or water detecting filters? While the contractor might not tell you, it is a good indicator of water problems. e) How often do you change out filters on planned maintenance on planned maintenance schedule? Quarterly, Biannual or Annual. If the contractor responds annually, then inspector should take extra efforts to look deeper into inspecting for presence of water. 7. Filter Cutter Opener and a Magnet One picture tells a thousand words. A filter cutter opener, which can be readily purchased on Amazon for under $100.00. (We use the Longacre brand) can tell inspector a lot about the condition of tanks. On the diesel filter, the inspectors should look for RUST Chips!!!!! Often the rust chips might be embedded in sludge or coffee grinds looking stuff………a magnet will confirm both metal and presence of water. Also, the inspectors should look for good ol’ nasty and gooey sludge. A sure sign of presence of water. This sludge can also create an acid which directly relates to deterioration of the fuel system. 8. Anti-Seize Product For any inspector who struggles with clamps, knobs or bolts on lifting sump lids or inspection plates, water and acid vapor contribute to the corrosion that makes the device not easy to remove. Go ahead and apply a little on threads……. this will make everyone’s job easier. 9. Non-Methylene Chloride Paint Stripper – Soy Based Paint Stripper. Since the problems of rusted STP motors came around in the mid 2000’s, manufacturers and contractors have attempted to protect such devices with paints and coatings. While it looks pretty and one can say they followed manufacturers recommendations, the acid vapors in the fuel system will deteriorate these coatings……including coating designed or aircrafts and applied properly. One these coating crack or peel, the water and acid vapors like to creep in and make some of nastiest corrosion known to mankind that can really wreak havoc. Even properly applied paint on properly prepped surfaces has rust breaking through. So, if you see paint peeling, chipping, or cracking, my advice is to remove it slowly and safely and then treat is with a true corrosion inhibitor that stands up to acid vapors. For safety reasons, choose a Non-Methylene Chloride Paint Stripper. These types of chemicals work by breaking the adhesion bond and not eating the coating. So, it might take a few days for it to work, then simply scrape or brush off with brass and properly dispose of. We have good luck with Soy Based Strippers and patience is the key. 10. Water Blocking Gel or Gaskets In 40 CFR 280 under section n § 280.36 Periodic operation and maintenance walkthrough inspections. There is a clause that states every 30 days spill prevention equipment must be inspected and that on must remove liquid or debris……and this covers spill buckets and water. And since no parking lots are perfectly level and delivery drivers are known not to be gentle on spill bucket lids, water is going to creep in. So, help yourself and your customers by making efforts to block water from entering the spill buckets and eventually the tank. One simple and cost-effective method is to employ water blocking gels and gaskets. These tools are particularly effective when spill buckets are located are located near snow piles or drains from canopies In summary, water directly and indirectly causes damage to fuel systems which increases the chances of a release. So, we recommend filling your inspector toolbox up with the proper tools to address water and employ early and often.

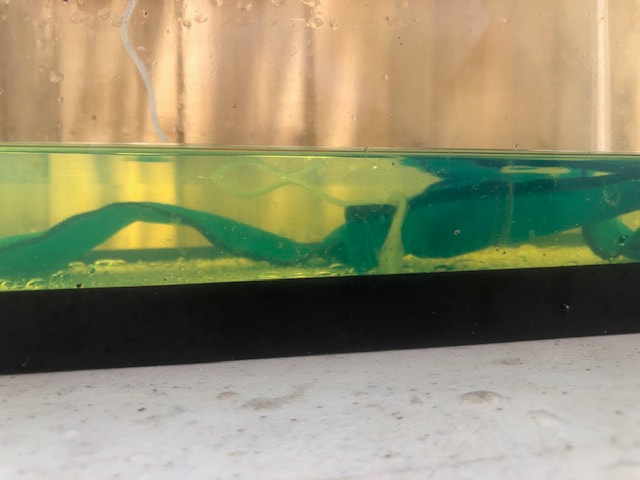

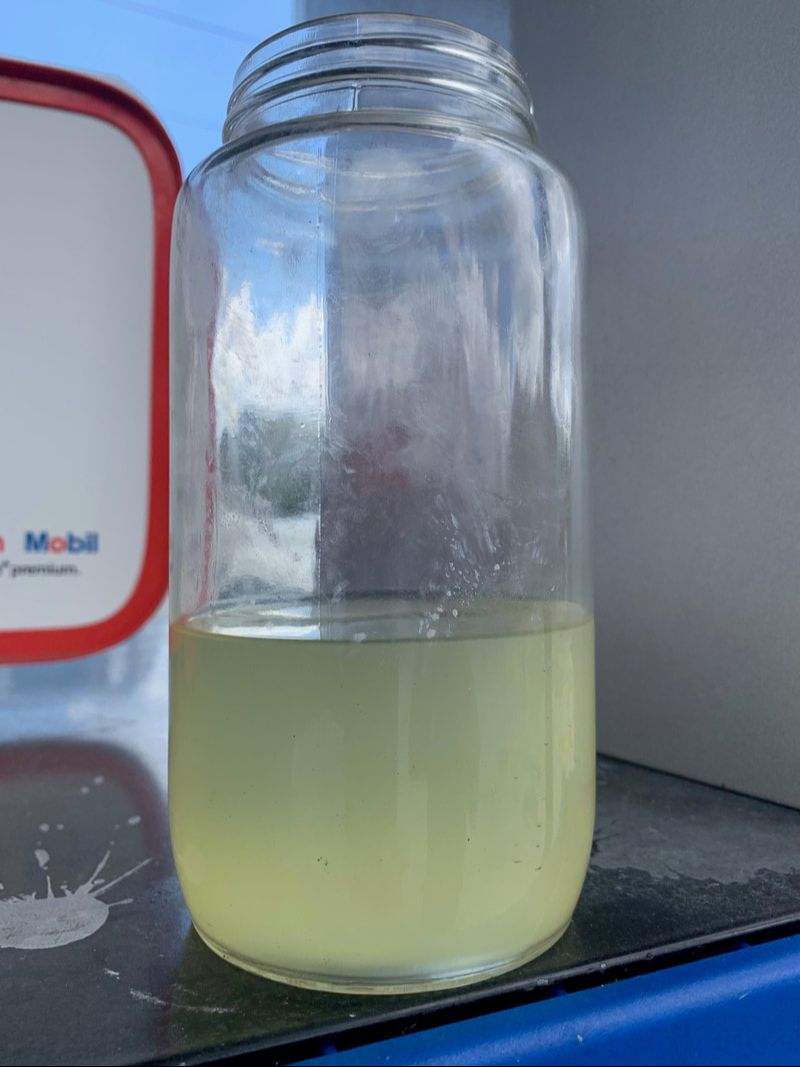

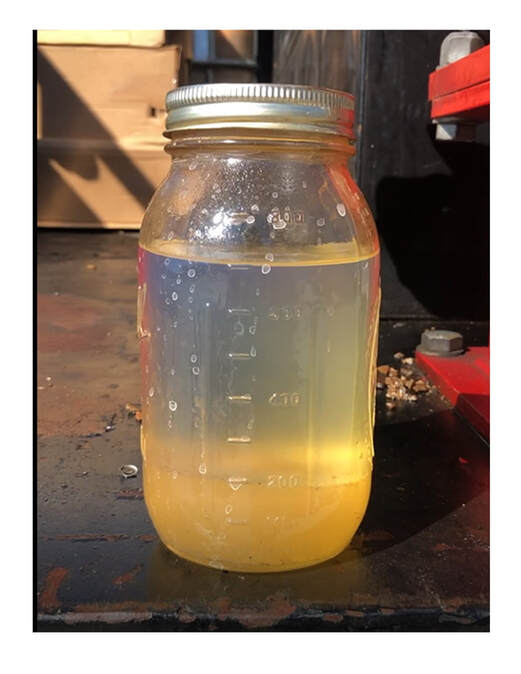

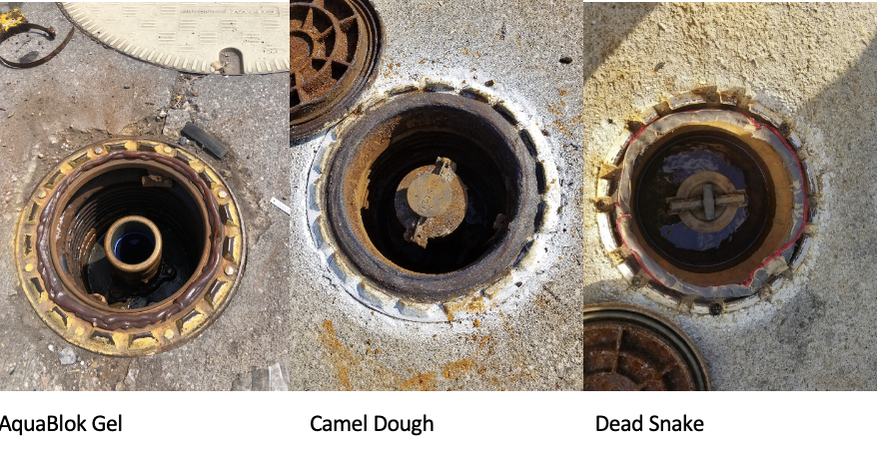

Author, Dan Jenkins – principal with Steel Camel Hello Everyone In UST Inspection World: Now that it has started to rain in Florida every day and other parts of the country are getting some heavy downpours, I wanted to take a minute to review parts of 40 CFR regulations regarding liquid in containment sumps and spill buckets. 40 CFR Parts 280 and 281 Revising Underground Storage Tank Regulations-- § 280.36 Periodic operation and maintenance walkthrough inspections. (a) To properly operate and maintain UST systems, not later than October 13, 2018 owners and operators must meet one of the following: (1) Conduct a walkthrough inspection that, at a minimum, checks the following equipment as specified below: (i) Every 30 days (Exception: spill prevention equipment at UST systems receiving deliveries at intervals greater than every 30 days may be checked prior to each delivery): (A) Spill prevention equipment— visually check for damage; remove liquid or debris; check for and remove obstructions in the fill pipe; check the fill cap to make sure it is securely on the fill pipe; In the photos, you will see the liquid which must be removed. Some questions for UST Inspectors and Station Owners can be: How is the liquid being remove what is the process to properly dispose of it. Is the liquid mostly fuel or water? or combination of both? How does one make the determination? Is there any correlation between this visible water, and water entering the tank? If so, Is fuel being visually inspected by a trained employee? If the station is employing a contractor to remove the liquid? If so, are they making attempts to prevent such breaches? There is a saying amongst accident investigators, if foreign liquid or water can enter the tank.....then there is possibilities fuel can exit the tank. Despite have secondary containment......water caused corrosion is still a risk should be nipped. The following are photos of sumps filled up with the water. Did this water come through a boot, a crack or a pipe? If so most owners and inspectors know of a good contractor to fix this. If the tank is tight, it is possible that the water is coming through the lid. If the water is coming though the lids, an option might be to check out Steel Camel's line of water blocking doughs, gels and flexible gaskets. Should any inspector, station owner or contractor wish to learn more about prevention of water intrustion, water caused corrosion and fuel contamination as it applies this regulation, contact Steel Camel. www.steelcamel.com

So, you are driving a big load across the country and you stop at several truck stops along way to refuel… …… everything is fine, and then a fuel filter / water warning light of some form on the dashboard appears and you are forced to pay attention. While not an emergency, it is certainly a concern, particularly to truck owners who hate being down with big repair bills. So, you get out the truck or take it to a mechanic and drain the water. It is usually a pet cock valve on the bottom of the filter, and the water is easily drained into a jar for proper disposal. This no big deal, unless you are having to do it weekly or every 5,000 miles or so. So, you ask your yourself… How did this happen?

To help truck owners avoid such problems, let’s dive a little deeper into the subject water in fuel. Why Is Water Content in Fuel So Bad for My Truck?

How Does Water Build Up in My Tanks? While this can take subject can take up the whole article, we will list a few reasons.

And since, truckers hate to wait around while pumping gas or slow pumps, the fuel is moved at up to 20 gpm per pump. At that flow rate, it is just really hard to block all the water from entering the tank.

Since changes in fuel laws in the mid 2000’s, there has been many changes in fuel chemistry to meet the demands of Alternative / Green Fuel Requirements. The trend of greener fuels such as Bio Diesel will continue and will leave out any discussion or arguments on energy independence or clean air regulations for another day. Due these greener fuels, the makeup has more organics such as corn, sugar, palm leaves, soybeans and animal parts. Many folks run their trucks on refined restaurant cooking oil grease. Those qualities are great for cleaner air, but also create the problem of water bonding to the alcohols, or the water / fuel combination is hydrophilic. This issue, with agitation over long trips creates the cloudy condition. What if My Fuel is Clear, But I Still Have to Drain Water in My Fuel Bowl? In many situations, the water will separate and fall to the bottom. In these cases, you fuel filter may not be able to catch it all, so the water ends up passing onto the fuel injector and combustion chamber and that can mean big trouble down the road. What Are My Options to Control The Water in My Fuel System?

It is a given the engine manufacturer want to sell you their OEM parts. So often, it is difficult to change the filter brand or type you purchase. They do this through special configurations, threads, tools and other means. Fortunately, there is the Magnuson Act which allows for aftermarket parts that won’t void the warranty. So, in choosing an aftermarket filter for water purposes, consider the following.

Yes this takes a little time and money to research, but a whole lot less than a fuel injector job and three days of no work.

Truckers know that being stranded away from home is a terrible experience. So, one way to avoid this in association with fuel problems is to remove water that settles in the tank. The independent / owner operator has several choices.

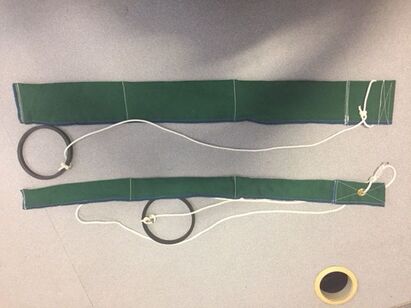

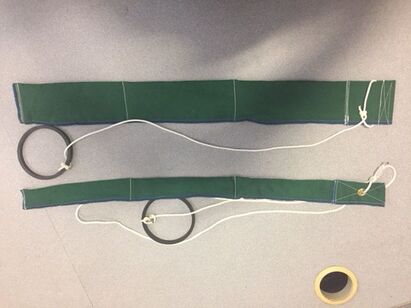

In a nutshell, it looks like an industrial Tampon and the sock with a rope that is inserted into the truck tank when idle for a day or more. The water will migrate to the sock and absorb into the chemistry. Then pull the sock out and place into a container or let it hang in a garage to air dry. Not all socks are created equal so you will have to consider:

Summary Don’t let water in your fuel system wreck your fuel injectors, schedule, budgets and bottom line. Pay attention to the water in the fuel filter bowl and lights on the dash and then tackle it, before it tackles you. Author: Dan Jenkins is a principal with Steel Camel, a manufacturer and distributor of water control products. While the act of locking guns in gun safes protects the guns from theft, this act also traps in moisture which can wreak havoc on metals, wood and valuables. So, to prevent havoc and worrying, we have created a document to review technologies and help gun owners tackle the moisture phenomenon. The Problem: Temperature Change & Condensation If you have ever touched a cold mirror after a hot shower or touched a side of the glass of ice tea on a hot day, you will notice condensation. In the gun safe world, this condensation forms as well when the safe is exposed to temperature swings. Most safes with condensation problems are the ones in garages, hunting cabins and ones hidden in walls with little insulation. For the safes kept in temperature-controlled houses or offices, the problem is less, but still can exist. Rust: Metal is negative and when exposed to condensation, the water droplets will act as an electrolyte and start an oxidation process which will lead to rust. It is this process which can wreak havoc on both interior and exterior parts of guns. Oil Based Protection (CLP) : Since the invention of metal in the bronze age that was used for protective armor, man has tried many barrier type methods and types of oils to keep the moisture off the metal. In the beginning, it was animal fat, then vegetable oil. In the last 200 years, petroleum oil has been used a barrier and many companies still use such formulas today with a few formulation twists. for cleaning and lubricating. Petroleum oil and greases are quite inexpensive, and manufacturers can create additive packages such as perfumes, cleaners to break down carbon build up and nonstick coatings to prevent build up. These all are fine and dandy, except the greases and oils can “dehydrate” and breakdown over time and thus leave the metal exposed. More on this subject on a future post. In addition, another problem with greases and oils as a barrier is they can act a dirt and debris magnet, thus creating its own set up problems…….particularly in the mechanical parts and barrels. So, experience tells us that for Cleaning, Lubricating and Protecting (CLP) of firearms it is really hard to find a great balance of all three…….so buyer beware. Solutions to Moisture in Safes So, if you go to gun shows, cruise the internet or visit gun stores seeking gun safe moisture solutions, you will probably end up with three main choices which that include:

Let’s Break Them Down with Pros and Cons.

Pros:

Taken from the boot drying industry, a heating element is placed horizontally at the bottom of the safe and a constant flow of warm air is dispensed 24 hours a day into the safe. The principle works by taking the warm moist air and rising it up and out of the safe where it can do little damage. The temperature ranges from 120-130F, a little too hot to hold, but not enough to burn. In order for this unit to work, it must have two holes, one for the electric cord or outlet, and one for the vent. Pros:

Taken from the hydraulic oil and fuel industry, this product called Moisture Hog by Steel Camel is a new entry into the desiccant market works much different than Silica Sand beads and other organic material. Instead of adsorbing moisture and sticking to beads where the moisture is still present, this product actually absorbs moisture and makes it inert. See video. https://www.youtube.com/watch?v=0U6kIsGj9X8&t=5s&ab_channel=SteelCamel This desiccant technology comes in an opaque bag of various sizes depending on the volume of air in the safe. While the Silica relies on a fan to draw in the moisture, Moisture Hog utilizes a powerful chemistry to attract and draw in the moisture. As the moisture is drawn in and captured, the bag with expand and blow up like the Pillsbury Doughboy. When blown up, it is time to change out and get a new bag. Pros:

Size L x W Volume Cu. Ft. # per case 1” x 2” 1-2’ 25 2” x 2” 3’ 25 3” x 3” 4-5’ 10 7” x7” 9-10’ 10 22” x 24’” Dependent 3 Cons:

Conclusion: Moisture caused corrosion can wreak havoc or even destroy your firearms and ammo in enclosed containers if not properly addressed. For the best practices, choose the best drying system that is safe, lasts a long time, has few bells and whistles, desiccates the greatest volume of air and affords the gun owner the most piece of mind. For more details, please contact Steel Camel @ [email protected] or visit www.steelcamel.com Boats are supposed to be for pleasure…….that is why the boating industry coined the phrase “Pleasure Boating” and taking a “Pleasure Cruise”. However, since the congressional acts some 13 years ago that brought in Ethanol Blended Fuel into the marine market, many “Pleasure Cruises” and Family Boating outings have turned sour due to water contaminated fuel. Even if the serious boater purchases “Rec Fuel” which contains no alcohol, there still can be water contaminated problems. This article / blog post will help shed some light on what causes such problems and what boaters and service techs can do to minimize the problems. First, let’s explore some issues. How Does Water Get Outboard Motor Fuel Tanks?

Why Is My Fuel Cloudy Sometimes, But Other Times Clear?

What Is So Bad About Suspended Water in My Fuel????

Corrosion on Fiberglass (l) and Steel (r)But What if I Already Have Fuel Water Separators to Catch Water? Won’t That Stop Water Entering My Engine? Not all fuel water separators work the same or catch all the water. Yes, you can buy a nice exterior fuel water separator that is easy to install, and has a clear bowl to let you know the water has been caught. However, what this type of filter does not tell you is how much water was able to get through to the engine. One principal used by fuel water separator manufacturer’s is called “coalescing” or the use of a coalescer. This technique takes small droplets and has actions to form them into bigger droplets, which when are directed to the outside of the filter housing. This water then falls down to a bowl and is easily drained with a pet cock valve. So, if you have such a fuel water separator, and you are experiencing poor performance, hard starts or black smoke, plus injector damage, it might that small water droplets are passing through and wreaking havoc. Examples of filters with glass bowls...how much water is getting through?So, What Are Some Steps I Can Take to Prevent and Remove Water, So I Don’t End Up With Water Contaminated Hazy Fuel in My Outboard Engine?

Water Absorbing Socks for Ethanol FuelsWhich filters are letting water through to the engine?

Fillrite RD 8 and Steel Camel Filters getting it doneSummary:

Water is meant swimming in pools, drinking, cooking, washing, sustaining life and many other great things. It has no good reason to be in outboard motor fuel tanks. Whether you are a boat dealer, marina, boat captain or service repair shop, pay attention to water and your headaches will go away. Seven Tips for UST Regulators to Help Station Owners Prevent UST Leaks and Comply with 40 CFR 2808/2/2020 By Dan Jenkins, Accident Prevention Specialist for Steel Camel. Short of a fueling station blowing up and / or catching on fire, there is nothing worse for station owners than a release of fuel into the public drinking water supply. Although it is very infrequent that these events occur, it does happen. So therefore, it is best for UST regulators stay aggressive and encourage “best preventative maintenance practices” so the chances of release are significantly minimized. This is particularly true in today’s environment with the advent of new fuels that have not been fully demonstrated to perform against corrosion in both new and old tank equipment. There is a saying amongst accident investigators, “small problems turn into big problem and small corrosion spots can turn into corrosion holes.” We have compiled a list of seven tips to help regulators and inspectors identify and correct commonly found corrosion issues….all of which are directly or indirectly related to water intrusion and many found in the latest version of 40 CFR 280. For reference purposes, we have taken some meaningful text from both the EPA OUST website and specific language from the standard itself. When a test or inspection occurs, owners and operators may find problems with the UST system. When a test or inspection indicates a problem, owners and operators must repair the problem to remain in compliance with this final UST regulation. Section 280.33 of this final UST regulation describes repair requirements for UST systems. § 280.36 Periodic operation and maintenance walkthrough inspections. (a) To properly operate and maintain UST systems, not later than October 13, 2018 owners and operators must meet one of the following: (1) Conduct a walkthrough inspection that, at a minimum, checks the following equipment as specified below:

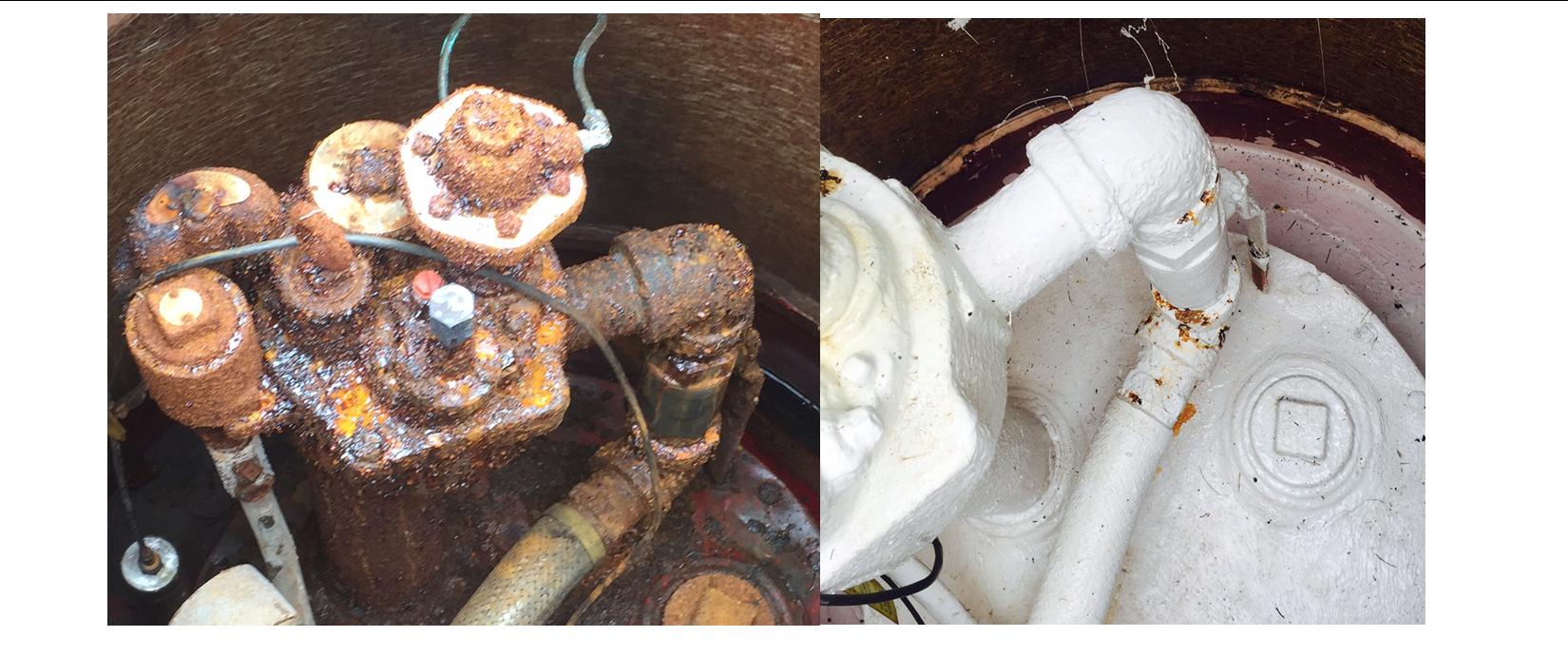

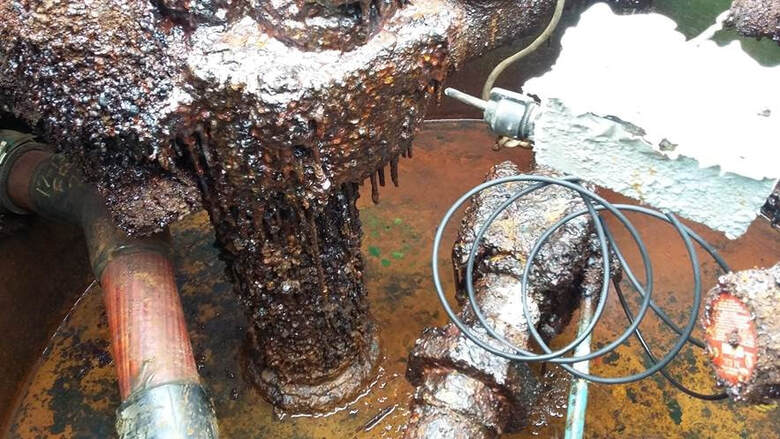

§ 280.43 Methods of release detection for tanks (6) The measurement of any water level in the bottom of the tank is made to the nearest one-eighth of an inch at least once a month. § 280.50 Reporting of suspected releases. Owners and operators of UST systems must report to the implementing agency within 24 hours, or another reasonable period specified by the implementing agency, and follow the procedures in § 280.52 for any of the following conditions: (a) (b) Unusual operating conditions observed by owners and operators (such an unexplained presence of water in the tank, TIP #1 – Better Understand thE Definition of Damage The 40 CFR 280 standard states owners must check for damage, but standard does not define what damage is………only if the equipment isn’t working properly and in need of repair. Also, the standard does also does not identify a measurement for corrosion, it left up to owners and inspectors to make that call. Here is a good rule of thumb to use that was eloquently explained by federal judge Potter Stewart as he attempted to explain "hard-core" pornography, or what is obscene, by saying, "I shall not today attempt further to define the kinds of material I understand to be embraced... “but I know it when I see it “... TIP #2 – MAKE CONNECTIONS WITH THE STATE DEPARTMENT OVERSEEING FUEL QUALITY INSPECTIONS This department is generally handled by Departments of Agriculture and they are important because these inspectors conduct tests for both free water and suspended water under the standard of National Institute of Standards and Technology (NIST) 130. This test calls for inspector to execute a test which draws fuel from the tank and inspect for clarity. If the fuel is not clear, it is primarily due to suspended water. Suspended water causes corrosion problems to both the tank, internal parts, piping and risers…..both in steel and FRP tanks. When regulators find station owners who repeatedly fail these visual tests, it makes sense to dig deeper why are these tanks having suspended water issues. Tip #3. Dig Deeper into Alarms Caused by Free Water While many contractors and station owner report all the alarms for high water level that go off, it is a good practice for regulators to investigate why such alarms do go off. 40 FR 280.50 requires that station owners explain the presence of excessive free water in the tank? Remember, if water can get into a tank, there are chances fuel can be release from a tank. Tip# 4. Dig Deeper to Why There is Excess Water in Sumps? Section 280.36 states sumps and spill bucket container must have liquid removed and if one digs deeper into the EPA OUST writings, they imply spill containers must be free of liquid. Inspectors should attempt to determine what percentage is water and what percentage is fuel. Is the lid or receptacle damaged?, was the lid improperly installed? Is there a crack in the lining? Or does the situation call simply for water blocking agents? Whatever the problem, regulators should do their best to help station owner correct the problem. Tip# 5. Dig Deeper to Why There is Excess Water in Spill Buckets? Just like tip #4, Excess water in spill buckets leads to problems. The same goes for inspection and installation of lids, however this tip features a whole new dynamic….delivery drivers. While the majority of drivers are professional, there is always a few bad apples who do not put lids on correctly or allow water to enter into openings. While these drivers are regulated under the Department of Transportation, its wise to find and interact with all delivery drivers and educate them on the importance of keeping tanks and containment devices free of water. TIP #6 – Advocate to Avoid Paint or Coatings in Sumps While it is perfectly legal for contractors to repaint turbine motors and piping to make them “oh so pretty,” there are often times numerous problems with paint in containment sumps.

Tip # 7 Ask to The See Used Fuel Filters Bin. While inspectors typically do not go this far, it might be wise to investigate these filters particularly if the station has history of alarms, repairs and fuel quality issues etc. The insides guts of filters can tell you a lot such as

If you are interested to learn more about the problems and solutions related to water and USTs, please contact Steel Camel at (813-877-4665). At Steel Camel we want to help regulators, contractors and tank owner avoid the most common and costly tank problems that can lead to a release. Introduction: Since water and moisture hover all around us, as well as hover around our computer boards and electrical parts, Circuit Board and Microelectronic manufacturers, assemblers and end users around the world are concerned about the effects of moisture causing corrosion on their products. There are many reasons for this concern, but the main one is board failure which can cause a major accident and or shutdown. So today, technology savvy companies turn to organizations like the Joint Electron Device Council (JEDEC) and Institute of Printed Circuit (IPC) to build some standards of performance which will help them:

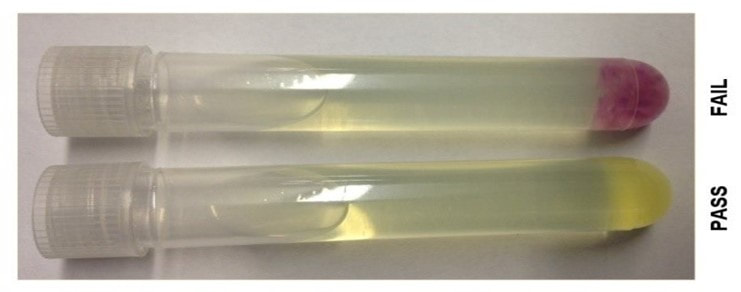

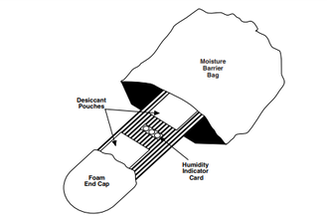

Today, JEDEC publishes a standard, J-STD-033, which provides guidance for reducing moisture during the handling, shipping, and storing on Moistures Sensitive Devices (MSD). In this standard, it states that MSDs must be stored in dry packs consisting of desiccant material and a Humidity Indicator Card (HIC), sealed with the MSD packaged inside a Moisture Barrier Bag (MBB). Additionally, the J-STD-033 goes on to reference which type of desiccant material should be used in the Dry Pack by referencing the desiccant referenced by the US Military specification, Mil-d- 3464. If one digs deep into this mil spec, as this author has done, one will find the spec refers to an adsorbent type of desiccant, not an absorbent type of desiccant………………….big difference! Also, for those who wish to dig a little deeper into the desiccant, you find out that Mil Spec d-3464 was written in 1967……………a lot has changed in circuit boards and microelectronics since that time……….so has the technology in desiccants. So, it wise for engineers to perform comparison tests to determine efficacy and performance. In previous posts and videos we have highlighted the differences and characteristics of adsorbents and absorbents: https://www.youtube.com/watch?v=0U6kIsGj9X8&t=15s. This post / article will examine how engineers and quality control managers can test and evaluate the performance of each desiccants bag technology so they can make the best decisions when it comes time package, store and maintain critical MSDs. What Tests Should Engineers Perform? There are basically four main tests that should be performed to determine the efficacy of different desiccant bags.

Test the materials at 25 degC (=/- 1degC) at a range of humidity from 20-80%RH. Start at 20% increments (20-40-60-80) and retest if there is any concern with smaller increments. The humidity tolerance will be +/- 2%RH. ** The tester should take equal weight Silica Bead and Expanding Polymeric bags and test for and record the following.

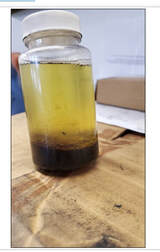

**This test procedure was supplied to Steel Camel by the engineer at the US Army. 2. Windowsill or Heat Lamp Test In this test, the engineer should take an absorbent bag (Polymeric) and adsorbent bag (Silica), the secure them both to two separate jar lids (tape or string) and then deposit a ¼ teaspoon of water in the bottom of the jar and close the lid. Let the jars sit in a windowsill that gets sun for three to five days and record the findings.

3. Shipping TestIn this test, you take an absorbent bag and adsorbent bag and place them in an MBB along with a HIC. Additionally, you introduce a few drops of water in the bag. You then mail the bags to various facilities in your organization or vendors you trust and ask them to open the MBB and record the findings of the HIC and the condition of the bag and its insides. Then ship the same set up back to your facility and record the findings. This test is valuable for companies that have multiple shipments of parts, particularly if they ship overseas.

4. Specific Environment Test In this test, the engineer would test the different bags in the MBB’s in harsh environments which their equipment will encounter. For example, a non airconditioned in warehouse in Florida can get quite humid in the summer times. Additional scenarios in include locations where temperatures can change over 35 degrees in a single day such as Denver, CO, or Chicago IL. Marine environments, glass atriums and frozen climates like Alaska can all be great places to conduct tests to help determine what type of bag offers the greatest control of moisture. The engineer should use the HIC card and the changes of weights of the different bags to help determine which bag provides the best results. Additional comparison tests engineers can perform:

Conclusion: I think we all can agree that desiccants play an important role in protecting critical parts from moisture causing corrosion in enclosed spaces. And, I think we can all agree that new technology comes around from time to time which proves to increase performance and productivity of specific processes…….remember the automobile replacing the horseless carriage and the cell phones maps replacing the paper maps? Finally, I think we call agree that marketers and advertisers can stretch the truth and use words that prove to be a contradictory in terms. Therefore, it is up to engineers to use their skills to determine the performance of specific products for specific applications to help their companies increase productivity and reliability, as well as reduce risk. We hope the above described tests will prove valuable to individual companies and the entire industry. References: J-STD-033 Mil Spec D 3464 US Army Packaging, Storage, and Containerization Center (PSCC) IPC-1601A Steel Camel www.steelcamel.com 813-877-4665 Service calls for rental companies of diesel equipment which involve hard starts, black smoke ( CA) and fuel injector problems is a royal pain in the butt. Steel Camel has put forth a presentation which explains the role of water management in Tier 4, High Pressure Common Rail Engines. The presentation review common best practices as well as some common mistakes fleet owner make. Oh Vey!!! Another sump and spill bucket water alarm goes off after a big rain or snow melt means another phone call from the gas station to the contractor. Unfortunately for the station owner, this means unwanted money spent on removal, storage, transporting and disposal of Petroleum Contact Water or PCW. Additional headaches for the station owner include

In the old days, station owners could just pump the water out and pour into the flower bed. But have many stations have learned the hard way…….contaminated flower beds and the soil underneath the beds is not only bad news from state environmental regulators, but big money when it comes time for an environmental assessment from banks and property owners. Additionally, many states a local government flat out forbid this practice and heavy fines or citations can be issued. If one takes a look at the EPA standard - 40 CFR Part 280, there is a specific section, 280.36, which states containment sumps and spill buckets shall be kept free of liquid and debris. And for those who inspect and maintain such equipment, they must make notes if liquid and debris are present. To reduce these problems, today’s savvy station owners are upgrading lids, leveling parking lots, raising concrete and containment areas, building new fuel pads etc. to combat water intrusion. That is great if the station has plenty of money, but even still, mother nature can wreak havoc. Fortunately, there is new technology from Steel Camel in the forms of water blocking gels, doughs and impregnated gaskets that offers a new and safe method to block water. The products are easily and safely applied by hand, and also easy to dispose of. This technology allows station owners either to have trained employees apply the product, or hire the service contractor supplying 30-day inspection services to apply the product. But What About the Contractors Who Make Money Removing, Storing, Transporting and Disposing of Water? Yes, there are some really good and reputable service and environmental companies that do a great job of removing, hauling and properly disposing water. Some make over $1.75 a gallon and have minimum charges of $600.00, and up to $800.00 in large metropolitan areas. While this may look good to the contractor from a billing standpoint, there are several problems with this model. Let’s take a look at just a few:

So… What Is The Answer for Contractors……….to pick up or block the water?

Since the implementation of EPA 40 CFR 280 standard and the introduction of Steel Camel water blocking technology, many of today’s savvy contractors are finding it more economical and a lot less headaches to provide blocking products and services rather remove and haul services. This is particularly true for those contractors who perform a) 30 day inspections, and b) see value in selling products off the truck during the service calls or inspections. And example of this is a contractor who see’s current and forecasted rain and they know they won’t be returning for 30 days, they sell a few tubes of Steel Camel AquaBlok Gel to Independent owners and operator who are willing to take 15 minutes to apply the product in exchange for no alarms going off and no bills for removal and disposal. For more information and the Steel Camel guide to blocking water, please contact 813-877-4665. Rubber Mats vs. Steel Camel to Block Water Intrusion in Sumps & Spill Buckets.Since the first containment sumps were required some 30 years ago, station owners, inspectors and contractors have struggled to keep water out of the sumps during big rains and snow melts……….particularly in our home state of Florida where it rains ping pong ball droplets for 4o minutes…….all summer long. This matter has increased importance since state and federal rules 40 CFR Part 280 now mandate that containment sumps must be kept free of all liquids and debris. The simplest answer is for a station owner to obtain a well-made lid and a matching well-made rubber gasket and then forget about it! Unfortunately, that situation doesn’t always work for a variety of reasons including:

Even with well made lids and matching gaskets, there are other issues such as excessive temperatures that cause expansions and cracks of concrete and metal. Some station owner are going to the lengths of rising the concrete an inch or two…….still, big rains are no match. So with water intrusion station owner have to take extra steps to avoid compliance violations, alarms and the high cost of water removal, storing, transporting and disposal. Speaking of disposal fees, In today’s world the larger “Vac Trucks” are requiring a $500 minimum to come pump out a 100 gallons. In todays world, there are a few options, 1) Rubber mats that act as a physical topical barrier. And 2), water blocking gels, doughs and gaskets where go underneath the lids and block water through both physical attributes and chemistry. Lets explore further. Rubber Mats can be purchased online and run anywhere form $50-80 for one 44” mat They weigh about 25 pounds and have a tendency to get heavier the more they soak up rain. The benefits are they will block the water over a long time if left un disturbed and everything works according to plan…………..but we are talking gas stations and lots of traffic. The drawbacks of rubber mats are many including:

Steel Camel Water Blocking Products Seeing that the rubber mats were not working very well, Steel Camel create water blocking products with its patented water blocking technology https://www.youtube.com/watch?v=QLj95QLErDs&t=10s . Each products works by suing the water blocking principals in the chemistry. The more it rains, the more they each block water. Three products are currently on the Steel Camel roster.

How Long Do the Products Last? The longevity of each product is different. The AquaBlok Gel is averaging 2-3 week at a normal station and 1-2 weeks at a super busy station. The application with a caulking gun is quite simple and costs about $9.00 per application. The Dead Snakes are lasting 3-4 months even during harsh winters and heavy rains. They products are meant to be used by contractors, store owners and inspectors who are maintaining the station and typically the ones to open lids. In summary, rubber mats look great on the surface…….until mother nature or the public kicks in……..both unavoidable. Steel Camel products have both innovative technology and innovative applications to solve this complex problem of water intrusion. For more information, please contact Steel Camel at 813-877-4665.

It is a given that UST sumps contain lots or dissimilar metals, often which are porous. It is also a given that there are going to some forms of water or humidity in the sumps. Also, some fuel vapors, primarily ones with organics (corn) excrete a bacteria that creates an acid. This combination results in rust that can wreak significant havoc and cause component to failure. One of the first attempts to combat this problem by industry contractors and station owners was to go to some form of paint or coating. The main reason is these products are readily available. The theory is that one can cover or smother the metal to cut off the oxygen, thus prevent rust. After seeing the results of rust coming back after six months, many contractors and station owners moved to more aggressive / durable coating and more aggressive preparation. Unfortunately, paint prep often involves removing metal, which ultimately weakens the metal. Another attempt by industry was to use an acid as preparation product such as Naval Jelly. The problems with this preparation is it requires a rinse, which creates a hazard waste. Also using acids in sumps can have negative effects on metal if not rinsed properly. The next problems contractors encountered with paints & coating was adhesion problems. The metals are porous, the surfaces are imperfect and not all metals readily accept paints and coatings. So many contractors tried to overcoat the surfaces and really smother the surfaces. What happens is the rust underneath the paint expands and causes blisters and paint no longer to adhere creating another set up problems. One problem is inspectors could not see rust hidden by the paint. Another problem was it became very difficult to remove fasteners and other components during repairs or replacement, thus increasing labor and safety concerns. Furthermore, removing paint in confined spaces is a major headache. Another problems with paints and coatings in sumps is they often the cure hard and become rigid. The problems with such characteristics is the pumps vibrate, and metals expand and contract during temperature swings. This can lead to cracks, which allow the water to creep under the paint and due further damage.

In summary, paints and coatings simply du not hold up well in confined spaces with humidity and vibration. Contractors and station owners are better off with corrosion treatments, such as the one Steel Camel offers. For additional information alternative products to paint to slow down corrosion, please contact Steel Camel at 813-877-4665 Dan Jenkins: Tampa, FL Long before electronic surface mount technologies were invented, moisture caused corrosion problems on metallic surfaces. From ancient swords and armor, to Egyptian jewelry to early telephone cable, metal components always want to return to its original state and the oxidation / corrosion problems process began. Early attempts to preserve and protect metal included animal fats, organic oils and coatings made from ashes, minerals and tree sap etc. In today’s world of surface mounted technology, the problems are no different. Metal components are placed in confined spaces and when temperatures change, humidity happens. When this liquid or vapor lands and sits on the metal, general corrosion occurs. Corrosion on boards causes failures, and failures cost the industry millions of dollars to fix. To protect these boards from failure moisture induced corrosion, manufacturers, assemblers and packagers have turned to different technologies to solve this issue. One way is with a conformal coating which is thin film. Often times they work great and there are no problems. Other times, the crack and cause all types of problems, including removal. In this article we will focus on different types of drying agents or desiccants. In another article we will cover other types of corrosion occur such as pitting, galvanic and stress. Let’s start of my understanding what a desiccant is and does. A desiccant is basically a drying agent. Most folks are accustomed to seeing them in pill bottles, vitamins and beef jerky. Today, many in the surface mount technology community are seeing them show up in individually packaged components. One of the reasons for this is the Military Specification D-3464. This specification was written in 1967 with minor revision in 1987….that was a long time ago. This spec calls for a desiccant which acts as an adsorbent, not be confused with an absorbent. While the words sound the same, they have different meanings. An adsorbent works by moisture sticking to the surface of desiccant. An absorbent works by the moisture being soaked up and held by the substrate. A baby diaper works on this principle; however, a baby diaper will not grab moisture from the air. If you get deeper into industry specs and industry standards such as the Joint Electron Device Engineering Council (JEDEC) Institute for Printed Circuits IPC, you will find they too reference the Mil-D-3464 spec, which includes a placement of adsorbent desiccant and a Humidity Indicator Card. So, what’s the problem? If the spec is good enough for the military and good enough for the two leading PCB / electronic associations, why should I care?.....Here is why… The adsorbent, often times referred to as Silica Gel Beads or Molecular Sieves are basically dried sand or Silica, baked in an oven. The baking creates tons of miniature cracks that help adhere the moisture to the surfaces. Sounds great on the surface, but let’s look a little deeper. Disadvantages of Silica GelThere are two main problems. First, due to the material being rigid, the beads do not hold much moisture. So, if your boards are sitting in a hot warehouse or on a ship with lots of temperature changes, the Silica Gel beads can’t handle the volume of moisture and the HIC is triggered. The second main problem is knockoffs and quality checks. Due to the low cost of raw materials, many bags are made overseas and in large volumes which makes quality control difficult. Advantages of Silica GelThey are incredibly inexpensive. A simple 2”x2’ bag can be as low as .25 cents and if you purchase them in China, you can get them for .12 cents. Another advantage of Silica Gel beads are they are treated with chemical dye which will provide a color change to alert the operator when to change out. There are some who claim Silica Gel beads can be regenerated in an oven, but with that low of price, why bother. Advantages of AbsorbentsAbsorbents, such as the Moisture Hog sold by Steel Camel, not only feature an expandable surface to grab more moisture, but they also hold the water by converting water into a non-water element and make it dry. See video youtube.com/watch?v=kli3OMrFUD4) Another advantage of Moisture Hog absorbent is will seek out moisture lurking in the package. Due to these features, the operator will be able to desiccate a much greater volume of air, thus put more board in per package. Often 10 to 15 time more volume. This feature saves labor and packaging material. Another advantage of Moisture Hog absorbent is the change indicator. Instead of a color change, the Moisture Hog bag will change shape and texture. Depending on the situation, it will either blow up like a pillow, or get hard like a rock to notify the operator a change is needed. Disadvantage of AbsorbentsThe Steel Camel Moisture Hog price per bag is more expensive compared to Silica Gel and Molecular Sieves. Often 10-15 times more (which offset by the volume of air desiccated) Another disadvantage is they chemistry cannot be regenerated. Finally, availability. Steel Camel is not Walmart or Amazon. Expect 5-7 days for delivery in the US, 8-12 days abroad. Summary:If you are not having and moisture problems, rejected shipments or component failures due to moisture, stick with Silica Gel Beads and Molecular Sieve adsorbents. If you are having such moisture problems, consider trying the Moisture Hog by Steel Camel…..particularly for your expensive critical moisture sensitive devices. Dan Jenkins, principal at Steel Camel can be reached at 813-877-4665 or [email protected]

|

�

AuthorIf you have any topics for review, please let us know. Archives

July 2024

Categories |

RSS Feed

RSS Feed