|

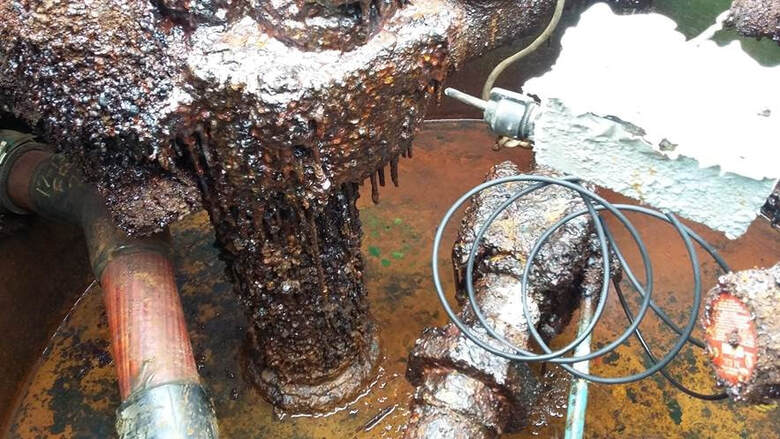

It is a given that UST sumps contain lots or dissimilar metals, often which are porous. It is also a given that there are going to some forms of water or humidity in the sumps. Also, some fuel vapors, primarily ones with organics (corn) excrete a bacteria that creates an acid. This combination results in rust that can wreak significant havoc and cause component to failure. One of the first attempts to combat this problem by industry contractors and station owners was to go to some form of paint or coating. The main reason is these products are readily available. The theory is that one can cover or smother the metal to cut off the oxygen, thus prevent rust. After seeing the results of rust coming back after six months, many contractors and station owners moved to more aggressive / durable coating and more aggressive preparation. Unfortunately, paint prep often involves removing metal, which ultimately weakens the metal. Another attempt by industry was to use an acid as preparation product such as Naval Jelly. The problems with this preparation is it requires a rinse, which creates a hazard waste. Also using acids in sumps can have negative effects on metal if not rinsed properly. The next problems contractors encountered with paints & coating was adhesion problems. The metals are porous, the surfaces are imperfect and not all metals readily accept paints and coatings. So many contractors tried to overcoat the surfaces and really smother the surfaces. What happens is the rust underneath the paint expands and causes blisters and paint no longer to adhere creating another set up problems. One problem is inspectors could not see rust hidden by the paint. Another problem was it became very difficult to remove fasteners and other components during repairs or replacement, thus increasing labor and safety concerns. Furthermore, removing paint in confined spaces is a major headache. Another problems with paints and coatings in sumps is they often the cure hard and become rigid. The problems with such characteristics is the pumps vibrate, and metals expand and contract during temperature swings. This can lead to cracks, which allow the water to creep under the paint and due further damage.

In summary, paints and coatings simply du not hold up well in confined spaces with humidity and vibration. Contractors and station owners are better off with corrosion treatments, such as the one Steel Camel offers. For additional information alternative products to paint to slow down corrosion, please contact Steel Camel at 813-877-4665

3 Comments

8/22/2022 09:44:45 am

It helped when you shared that paint or coating is used to prevent rust on steel. My friend told me that their project includes substation painting. I think it's best for them to partner with a contractor that specializes in substation painting for the success of the project.

Reply

5/17/2023 07:30:51 am

Avoiding paint coatings in sumps and other tight locations is stressed in a recent blog article by Steel Camel. It highlights the need of adopting appropriate alternatives and explores the potential dangers and risks of paint coatings in such settings. The post raises awareness and promotes safer practices in dealing with sumps and restricted spaces by providing relevant insights supported by industry knowledge and expertise.

Reply

Leave a Reply. |

�

AuthorIf you have any topics for review, please let us know. Archives

July 2024

Categories |

RSS Feed

RSS Feed