Seven Tips for UST Regulators to Help Station Owners Prevent UST Leaks and Comply with 40 CFR 2808/2/2020 By Dan Jenkins, Accident Prevention Specialist for Steel Camel. Short of a fueling station blowing up and / or catching on fire, there is nothing worse for station owners than a release of fuel into the public drinking water supply. Although it is very infrequent that these events occur, it does happen. So therefore, it is best for UST regulators stay aggressive and encourage “best preventative maintenance practices” so the chances of release are significantly minimized. This is particularly true in today’s environment with the advent of new fuels that have not been fully demonstrated to perform against corrosion in both new and old tank equipment. There is a saying amongst accident investigators, “small problems turn into big problem and small corrosion spots can turn into corrosion holes.” We have compiled a list of seven tips to help regulators and inspectors identify and correct commonly found corrosion issues….all of which are directly or indirectly related to water intrusion and many found in the latest version of 40 CFR 280. For reference purposes, we have taken some meaningful text from both the EPA OUST website and specific language from the standard itself. When a test or inspection occurs, owners and operators may find problems with the UST system. When a test or inspection indicates a problem, owners and operators must repair the problem to remain in compliance with this final UST regulation. Section 280.33 of this final UST regulation describes repair requirements for UST systems. § 280.36 Periodic operation and maintenance walkthrough inspections. (a) To properly operate and maintain UST systems, not later than October 13, 2018 owners and operators must meet one of the following: (1) Conduct a walkthrough inspection that, at a minimum, checks the following equipment as specified below:

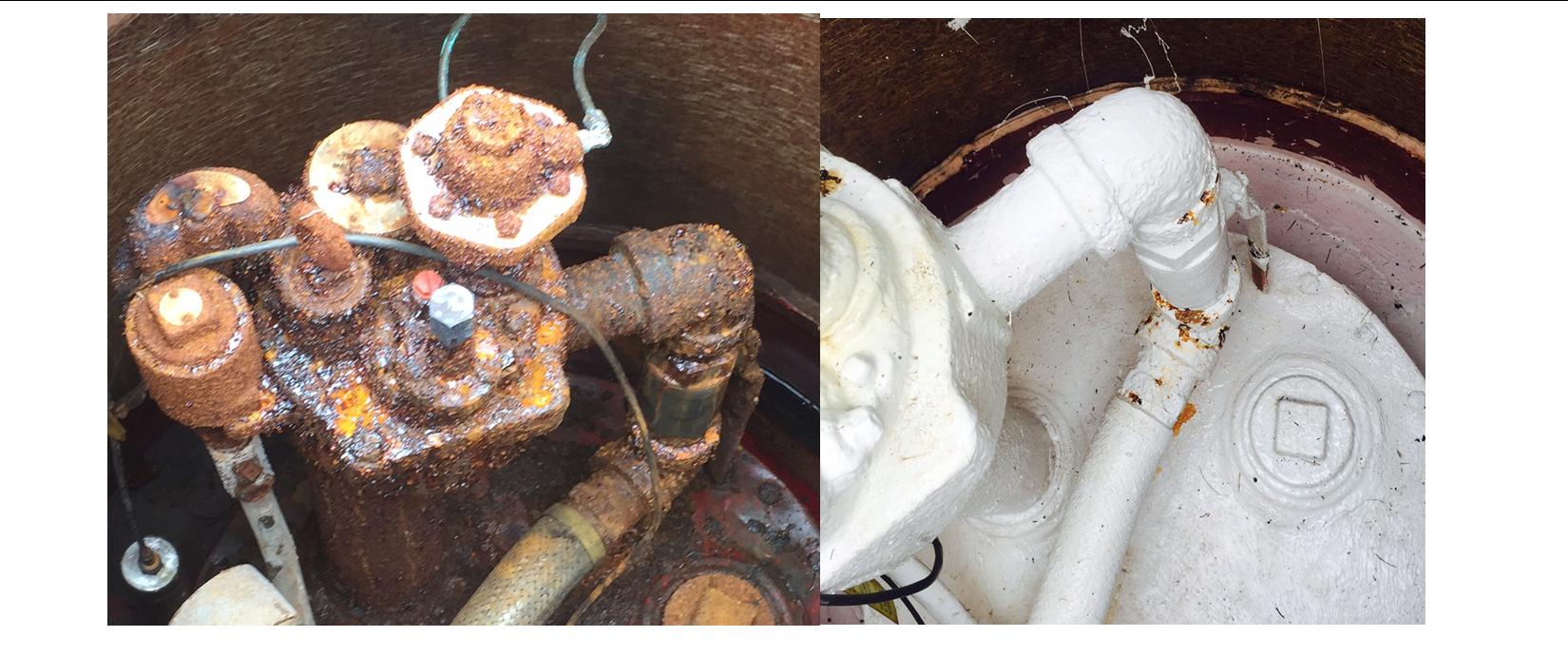

§ 280.43 Methods of release detection for tanks (6) The measurement of any water level in the bottom of the tank is made to the nearest one-eighth of an inch at least once a month. § 280.50 Reporting of suspected releases. Owners and operators of UST systems must report to the implementing agency within 24 hours, or another reasonable period specified by the implementing agency, and follow the procedures in § 280.52 for any of the following conditions: (a) (b) Unusual operating conditions observed by owners and operators (such an unexplained presence of water in the tank, TIP #1 – Better Understand thE Definition of Damage The 40 CFR 280 standard states owners must check for damage, but standard does not define what damage is………only if the equipment isn’t working properly and in need of repair. Also, the standard does also does not identify a measurement for corrosion, it left up to owners and inspectors to make that call. Here is a good rule of thumb to use that was eloquently explained by federal judge Potter Stewart as he attempted to explain "hard-core" pornography, or what is obscene, by saying, "I shall not today attempt further to define the kinds of material I understand to be embraced... “but I know it when I see it “... TIP #2 – MAKE CONNECTIONS WITH THE STATE DEPARTMENT OVERSEEING FUEL QUALITY INSPECTIONS This department is generally handled by Departments of Agriculture and they are important because these inspectors conduct tests for both free water and suspended water under the standard of National Institute of Standards and Technology (NIST) 130. This test calls for inspector to execute a test which draws fuel from the tank and inspect for clarity. If the fuel is not clear, it is primarily due to suspended water. Suspended water causes corrosion problems to both the tank, internal parts, piping and risers…..both in steel and FRP tanks. When regulators find station owners who repeatedly fail these visual tests, it makes sense to dig deeper why are these tanks having suspended water issues. Tip #3. Dig Deeper into Alarms Caused by Free Water While many contractors and station owner report all the alarms for high water level that go off, it is a good practice for regulators to investigate why such alarms do go off. 40 FR 280.50 requires that station owners explain the presence of excessive free water in the tank? Remember, if water can get into a tank, there are chances fuel can be release from a tank. Tip# 4. Dig Deeper to Why There is Excess Water in Sumps? Section 280.36 states sumps and spill bucket container must have liquid removed and if one digs deeper into the EPA OUST writings, they imply spill containers must be free of liquid. Inspectors should attempt to determine what percentage is water and what percentage is fuel. Is the lid or receptacle damaged?, was the lid improperly installed? Is there a crack in the lining? Or does the situation call simply for water blocking agents? Whatever the problem, regulators should do their best to help station owner correct the problem. Tip# 5. Dig Deeper to Why There is Excess Water in Spill Buckets? Just like tip #4, Excess water in spill buckets leads to problems. The same goes for inspection and installation of lids, however this tip features a whole new dynamic….delivery drivers. While the majority of drivers are professional, there is always a few bad apples who do not put lids on correctly or allow water to enter into openings. While these drivers are regulated under the Department of Transportation, its wise to find and interact with all delivery drivers and educate them on the importance of keeping tanks and containment devices free of water. TIP #6 – Advocate to Avoid Paint or Coatings in Sumps While it is perfectly legal for contractors to repaint turbine motors and piping to make them “oh so pretty,” there are often times numerous problems with paint in containment sumps.

Tip # 7 Ask to The See Used Fuel Filters Bin. While inspectors typically do not go this far, it might be wise to investigate these filters particularly if the station has history of alarms, repairs and fuel quality issues etc. The insides guts of filters can tell you a lot such as

If you are interested to learn more about the problems and solutions related to water and USTs, please contact Steel Camel at (813-877-4665). At Steel Camel we want to help regulators, contractors and tank owner avoid the most common and costly tank problems that can lead to a release.

1 Comment

|

�

AuthorIf you have any topics for review, please let us know. Archives

July 2024

Categories |

RSS Feed

RSS Feed