|

Introduction: Since water and moisture hover all around us, as well as hover around our computer boards and electrical parts, Circuit Board and Microelectronic manufacturers, assemblers and end users around the world are concerned about the effects of moisture causing corrosion on their products. There are many reasons for this concern, but the main one is board failure which can cause a major accident and or shutdown. So today, technology savvy companies turn to organizations like the Joint Electron Device Council (JEDEC) and Institute of Printed Circuit (IPC) to build some standards of performance which will help them:

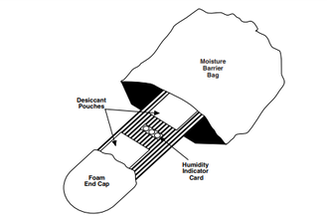

Today, JEDEC publishes a standard, J-STD-033, which provides guidance for reducing moisture during the handling, shipping, and storing on Moistures Sensitive Devices (MSD). In this standard, it states that MSDs must be stored in dry packs consisting of desiccant material and a Humidity Indicator Card (HIC), sealed with the MSD packaged inside a Moisture Barrier Bag (MBB). Additionally, the J-STD-033 goes on to reference which type of desiccant material should be used in the Dry Pack by referencing the desiccant referenced by the US Military specification, Mil-d- 3464. If one digs deep into this mil spec, as this author has done, one will find the spec refers to an adsorbent type of desiccant, not an absorbent type of desiccant………………….big difference! Also, for those who wish to dig a little deeper into the desiccant, you find out that Mil Spec d-3464 was written in 1967……………a lot has changed in circuit boards and microelectronics since that time……….so has the technology in desiccants. So, it wise for engineers to perform comparison tests to determine efficacy and performance. In previous posts and videos we have highlighted the differences and characteristics of adsorbents and absorbents: https://www.youtube.com/watch?v=0U6kIsGj9X8&t=15s. This post / article will examine how engineers and quality control managers can test and evaluate the performance of each desiccants bag technology so they can make the best decisions when it comes time package, store and maintain critical MSDs. What Tests Should Engineers Perform? There are basically four main tests that should be performed to determine the efficacy of different desiccant bags.

Test the materials at 25 degC (=/- 1degC) at a range of humidity from 20-80%RH. Start at 20% increments (20-40-60-80) and retest if there is any concern with smaller increments. The humidity tolerance will be +/- 2%RH. ** The tester should take equal weight Silica Bead and Expanding Polymeric bags and test for and record the following.

**This test procedure was supplied to Steel Camel by the engineer at the US Army. 2. Windowsill or Heat Lamp Test In this test, the engineer should take an absorbent bag (Polymeric) and adsorbent bag (Silica), the secure them both to two separate jar lids (tape or string) and then deposit a ¼ teaspoon of water in the bottom of the jar and close the lid. Let the jars sit in a windowsill that gets sun for three to five days and record the findings.

3. Shipping TestIn this test, you take an absorbent bag and adsorbent bag and place them in an MBB along with a HIC. Additionally, you introduce a few drops of water in the bag. You then mail the bags to various facilities in your organization or vendors you trust and ask them to open the MBB and record the findings of the HIC and the condition of the bag and its insides. Then ship the same set up back to your facility and record the findings. This test is valuable for companies that have multiple shipments of parts, particularly if they ship overseas.

4. Specific Environment Test In this test, the engineer would test the different bags in the MBB’s in harsh environments which their equipment will encounter. For example, a non airconditioned in warehouse in Florida can get quite humid in the summer times. Additional scenarios in include locations where temperatures can change over 35 degrees in a single day such as Denver, CO, or Chicago IL. Marine environments, glass atriums and frozen climates like Alaska can all be great places to conduct tests to help determine what type of bag offers the greatest control of moisture. The engineer should use the HIC card and the changes of weights of the different bags to help determine which bag provides the best results. Additional comparison tests engineers can perform:

Conclusion: I think we all can agree that desiccants play an important role in protecting critical parts from moisture causing corrosion in enclosed spaces. And, I think we can all agree that new technology comes around from time to time which proves to increase performance and productivity of specific processes…….remember the automobile replacing the horseless carriage and the cell phones maps replacing the paper maps? Finally, I think we call agree that marketers and advertisers can stretch the truth and use words that prove to be a contradictory in terms. Therefore, it is up to engineers to use their skills to determine the performance of specific products for specific applications to help their companies increase productivity and reliability, as well as reduce risk. We hope the above described tests will prove valuable to individual companies and the entire industry. References: J-STD-033 Mil Spec D 3464 US Army Packaging, Storage, and Containerization Center (PSCC) IPC-1601A Steel Camel www.steelcamel.com 813-877-4665

2 Comments

Leave a Reply. |

�

AuthorIf you have any topics for review, please let us know. Archives

July 2024

Categories |

RSS Feed

RSS Feed